Stay Ahead in Fast-Growing Economies.

Browse Reports NowCooling Tower Market Size, Share, Growth & Forecast (2024-2032)

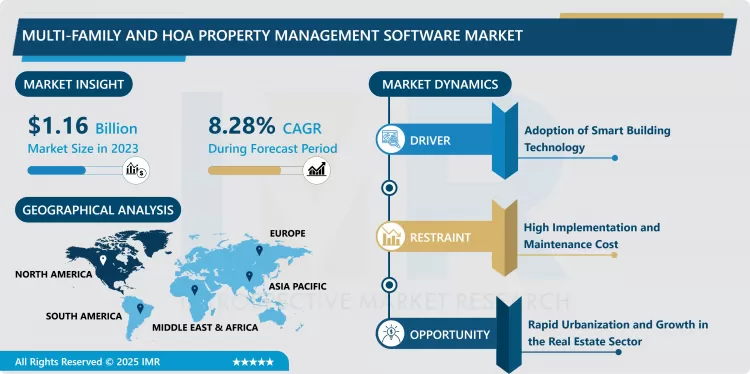

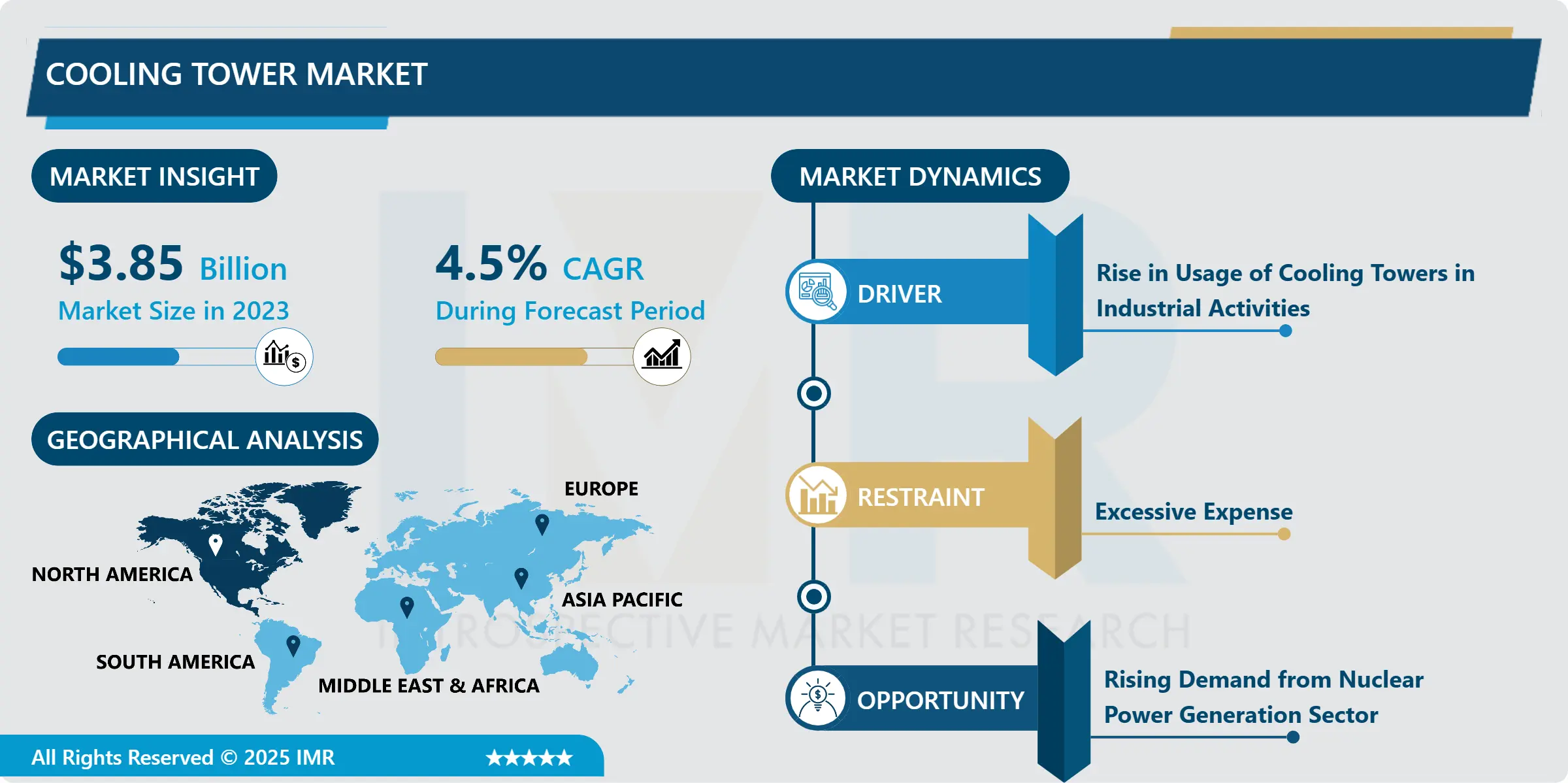

Cooling Tower Market Size Was Valued at USD 3.85 Billion in 2023, and is Projected to Reach USD 5.72 Billion by 2032, Growing at a CAGR of 4.50% From 2024-2032.

IMR Group

Description

Cooling Tower Market Synopsis:

Cooling Tower Market Size Was Valued at USD 3.85 Billion in 2023, and is Projected to Reach USD 5.72 Billion by 2032, Growing at a CAGR of 4.50% From 2024-2032.

A cooling tower is a heat exchanger that does not use water to cool the structures and depends on it to transfer waste heat to the environment. It has many benefits including cost and energy saving, water saving, perfect cooling ability and resistance to corrosion, install easily and it has high strength structure and long service life and low noise. Therefore, it is applied in ventilation, heating as well as air conditioning (HVAC), power generation, oil refining, cold storage facilities and food processing. In addition, it is used for gentle and effective cooling in various large-scale industrial and non-industrial buildings which include hospitals, airports, schools, hotels and so on, among them.

There has been tremendous growth and trends in the consumer global cooling tower market due to enhanced need to curb energy consumption by industries dealing with companies in power generation, manufacturing, and HVAC systems. Cooling towers are essential parts of heat processes in industries where they use the working fluid to expel heat in the atmosphere. Their main task is to regulate the temperature of water used in cooling processes in industries, which has a direct bearing in determining efficiency because of risks of overheating. Some of the factors that affect the market include; The growth in industrialization and urbanization across the world; Expansion of power generation plants; and the development of new infrastructure especially in the growth regions of the world.

Other factors that have driven the growth of the market includes development of improved, energy efficient and eco-friendly and cheaper cooling systems among others. Several organizations are now embracing closed-circuit cooling towers and those that are a combination of other features that help to conserve water while at the same time improving on the cooling capacity. Furthermore, with increasing consciousness about sustainability and legal requirements concerning water usage for cooling and energy consumption for the cooling purposes, the industries had to focus on the modern cooling economics. The cooling tower market is also enjoying the increase of industrial requirements in Oil & Gas, Chemical Processing and Refrigeration sectors where businesses require giant cooling systems. Nevertheless, some drawbacks such as greater initial installation costs or associated maintenance costs, combined with the emerging problems that demand increased attention be paid to water provision, act as restraints to market expansion. Thus, at the same time, the mainstream focus on energy saving technologies and environment friendly products presents significant potential for further development and investment within the industry.

Cooling Tower Market Trend Analysis:

Advancements in Energy Efficiency and Water Conservation Driving Cooling Tower Market Growth

There is a general trend of conversion towards energy efficient cooling tower solutions due to increase energy costs as well as becoming and higher standards of environmental legislations. New generations of cooling towers are being installed in industries and commercial spaced that keep power consumption to the lowest levels and provide optimum performance. To meet this need, global producers are employing premium-class materials including high-feature plastics and corrosion-resistant composites to optimize the sturdiness and effectiveness of cooling equipments. These materials not only extend the service life of the cooling towers but also enhance their thermal characteristics making them capable of serving in numerous related industrial functions.

Along with energy efficiency, water savings are emerging as a new major trend in cooling tower design and development. There is increasing adoption of hybrid cooling systems and water efficient designs as more and more organizations look to cut down their costs. These systems work with improved technologies to reduce water usage in cooling while at the same time staying relevant to sustainability agendas. This growing preference for applied resource-efficient cooling solutions is speeding up the market development as industries turn their focus to sustainability, owing to legal restrictions, as well as customer demands.

Emerging Opportunities in the Cooling Tower Market

Rising uptake of HVAC systems in the residential and commercial buildings as well as in industries has been a major factor for increased need for energy efficient coolants. Due to the increasing rate of growth in urban and industrial centers, there is need to control temperature and this is more so in areas where climate is extreme. Government across the globe have set very strict standards of regulating emissions to carbon, thus increasing pressure on industries to adopt new technologies in cooling tower, thus providing high-performance and eco-friendly cooling towers. This shift is opening up a rapidly growing market for new cooling tower technologies that conform to sustainability schemes, which in turn is providing a considerable niche for cool tower manufacturers catering directly to these green markets.

However, increasing regulatory and environmental concerns have forced changes in the types of cooling towers being created faster than material and design improvements are in development. Advancements like corrosion resistant ones, modularity in design and cooling tower hybrid solutions, are making it possible to bring improvements in the areas of durability, energy consumption and water conservation. Such developments not only reduce operating expenses but also supply adjustable answers to sectors that have different cooling requirements. It makes a good prospect for manufactures to penetrate the market with durable and affordable products since the people are demanding sustainable solutions in a competitive world economy.

Cooling Tower Market Segment Analysis:

Cooling Tower Market is Segmented on the basis of By Type, Application, Design, Construction Material, End-user, and Region.

By Type, Open-Circuit Cooling Towers segment is expected to dominate the market during the forecast period

Operating cooling towers are of the open circuit and this design enables water to come into direct contact with air so that heat exchange through evaporative means is made possible. When the warm water is being introduced into the tower then it is forced to come into contact with air, heating from which is taken away convection by evaporating part of the water. The cooled water is then pumped back to the industrial process The water exits the industrial process is then cooled to a desired level. These cooling towers are commonly used in generation of power, Chemical production or manufacturing units where there is need to cool large body of water. They are cheap to make due to their construction and also because they transfer heat well, for this reason they cannot be used in jurisdictions where water is scarce.

Still, open circuit cooling tower must be maintained usually for proper functioning of the circuit. Without channeling, the confined water and air lead to scaling and fouling and biomass growth such as algae and bacteria that cause blockage in the system affecting temperature transfer rate. Therefore, common characteristics of these cooling towers include constant demand for cleaning, water treatment and inspection. However, due to versatility and lesser initial investment, open circuit cooling towers are most commonly used in many industrial applications where operations costs and cooling effectiveness are of paramount importance.

By End-user, Chemical segment expected to held the largest share

In production processes, cooling towers are used to cool various chemicals during production processes across the industry. These towers control excessive heat in vessels, reactors, and other equipments for the optimum rate of the reactions. However, the stabilizing chemical processes may be disrupted through poor cooling, reducing the efficiency and increasing energy demands as well as the risk of hazards. Towers in this sector have to accommodate hot fluids, particularly where the process involves or is accompanied by strong or heat-producing reactions, with definitive temperature stability for the whole facility.

Due to aggressive and corrosive nature of substances used in the chemical industry, the cooling towers used in this industry should be made from strong material. These products include Fiber-Reinforced Plastic (FRP) and High-Density Polyethylene (HDPE) because of their accordant abilities to withstand harsh chemical solutions andweather degradation. These materials assist in increasing the cooling tower age and reduce maintenance costs as well. There are several important aspects of cooling system designs for manufactured structures, but one of the most important is the use of only long-lasting and highly-resistant to corrosion materials as it is important to supply cooling systems which do not fail and do not require major repairings which may slow down manufacturing processes.

Cooling Tower Market Regional Insights:

North America is Expected to Dominate the Market Over the Forecast period

North America has emerged as another significant participant in the universal cooling tower market owing to its strong industrialisation across diversified domains including power generation, oil and gas industry and chemical production. This has been driven by the need for improved energy efficiency and conservations hence organisations in the region are employing sophisticated cooling solutions. This is also supported by strict environmental standards that crank up pressure for lower carbon and water usage offering a favorable market environment for the sector. Among North America, the United States is crucial as it has a large industrial base and an active regulatory environment that reinforcing consumers’ demand for new age cooling tower systems.

Besides regulation, technological contributing factors have remained as one of the major influential factors for North American cooling tower market. Smart monitoring systems and advanced cooler systems are allowing industries to optimise their performance while at the same time reducing their carbon footprint. These systems deliver raw data in real time so that it can be used for purposes such as predictive maintenance and more efficient energy consumption; something that is beneficial to various industries in a bid to cut expenses incurred during operations. Therefore, North America remains the market that remains in the process of strengthening the leadership of using innovative cooling tower solutions, therefore providing the market with constant growth.

Active Key Players in the Cooling Tower Market

Amcor plc (Australia) EVAPCO (U.S.)

Artech Cooling Towers Pvt. Ltd. (India)

Babcock & Wilcox Enterprises (U.S.)

Baltimore Aircoil Company (U.S.)

Baltimore Aircoil Company Inc. (U.S.)

BELL COOLING TOWERS (India)

Brentwood Industries (U.S.)

Cannon Water Technology (U.S.)

Delta Cooling Towers (U.S.)

ENEXIO MANAGEMENT GMBH (Germany)

Hamon & CIE International (Belgium)

International Cooling Tower (Canada)

Johnson Controls Inc. (Ireland)

MESAN Group (China)

NALCO India (India)

Paharpur Cooling Tower Ltd. (India)

Paharpur Cooling Towers Ltd. (India)

Perfect Star Heating and Air Conditioning, Inc (U.S.)

REYMSA COOLING TOWERS, INC, (U.S.)

SPX Corporation (U.S.)

Star Cooling Towers (India)

Thermax Limited (India)

Other Active Players.

Chapter 1: Introduction

1.1 Scope and Coverage

Chapter 2:Executive Summary

Chapter 3: Market Landscape

3.1 Market Dynamics

3.1.1 Drivers

3.1.2 Restraints

3.1.3 Opportunities

3.1.4 Challenges

3.2 Market Trend Analysis

3.3 PESTLE Analysis

3.4 Porter’s Five Forces Analysis

3.5 Industry Value Chain Analysis

3.6 Ecosystem

3.7 Regulatory Landscape

3.8 Price Trend Analysis

3.9 Patent Analysis

3.10 Technology Evolution

3.11 Investment Pockets

3.12 Import-Export Analysis

Chapter 4: Cooling Tower Market by Type

4.1 Cooling Tower Market Snapshot and Growth Engine

4.2 Cooling Tower Market Overview

4.3 Open-Circuit Cooling Towers

4.3.1 Introduction and Market Overview

4.3.2 Historic and Forecasted Market Size in Value USD and Volume Units (2017-2032F)

4.3.3 Key Market Trends, Growth Factors and Opportunities

4.3.4 Open-Circuit Cooling Towers: Geographic Segmentation Analysis

4.4 Closed-Circuit Cooling Towers

4.4.1 Introduction and Market Overview

4.4.2 Historic and Forecasted Market Size in Value USD and Volume Units (2017-2032F)

4.4.3 Key Market Trends, Growth Factors and Opportunities

4.4.4 Closed-Circuit Cooling Towers: Geographic Segmentation Analysis

4.5 Hybrid Cooling Towers

4.5.1 Introduction and Market Overview

4.5.2 Historic and Forecasted Market Size in Value USD and Volume Units (2017-2032F)

4.5.3 Key Market Trends, Growth Factors and Opportunities

4.5.4 Hybrid Cooling Towers: Geographic Segmentation Analysis

Chapter 5: Cooling Tower Market by Application

5.1 Cooling Tower Market Snapshot and Growth Engine

5.2 Cooling Tower Market Overview

5.3 Cross Flow

5.3.1 Introduction and Market Overview

5.3.2 Historic and Forecasted Market Size in Value USD and Volume Units (2017-2032F)

5.3.3 Key Market Trends, Growth Factors and Opportunities

5.3.4 Cross Flow: Geographic Segmentation Analysis

5.4 Counter Flow

5.4.1 Introduction and Market Overview

5.4.2 Historic and Forecasted Market Size in Value USD and Volume Units (2017-2032F)

5.4.3 Key Market Trends, Growth Factors and Opportunities

5.4.4 Counter Flow: Geographic Segmentation Analysis

Chapter 6: Cooling Tower Market by Design

6.1 Cooling Tower Market Snapshot and Growth Engine

6.2 Cooling Tower Market Overview

6.3 Mechanical Draft Cooling Tower

6.3.1 Introduction and Market Overview

6.3.2 Historic and Forecasted Market Size in Value USD and Volume Units (2017-2032F)

6.3.3 Key Market Trends, Growth Factors and Opportunities

6.3.4 Mechanical Draft Cooling Tower: Geographic Segmentation Analysis

6.4 Natural Draft Cooling Tower

6.4.1 Introduction and Market Overview

6.4.2 Historic and Forecasted Market Size in Value USD and Volume Units (2017-2032F)

6.4.3 Key Market Trends, Growth Factors and Opportunities

6.4.4 Natural Draft Cooling Tower: Geographic Segmentation Analysis

Chapter 7: Cooling Tower Market by Construction Material

7.1 Cooling Tower Market Snapshot and Growth Engine

7.2 Cooling Tower Market Overview

7.3 Fiber-Reinforced Plastic

7.3.1 Introduction and Market Overview

7.3.2 Historic and Forecasted Market Size in Value USD and Volume Units (2017-2032F)

7.3.3 Key Market Trends, Growth Factors and Opportunities

7.3.4 Fiber-Reinforced Plastic : Geographic Segmentation Analysis

7.4 Steel

7.4.1 Introduction and Market Overview

7.4.2 Historic and Forecasted Market Size in Value USD and Volume Units (2017-2032F)

7.4.3 Key Market Trends, Growth Factors and Opportunities

7.4.4 Steel: Geographic Segmentation Analysis

7.5 Concrete

7.5.1 Introduction and Market Overview

7.5.2 Historic and Forecasted Market Size in Value USD and Volume Units (2017-2032F)

7.5.3 Key Market Trends, Growth Factors and Opportunities

7.5.4 Concrete: Geographic Segmentation Analysis

7.6 Wood

7.6.1 Introduction and Market Overview

7.6.2 Historic and Forecasted Market Size in Value USD and Volume Units (2017-2032F)

7.6.3 Key Market Trends, Growth Factors and Opportunities

7.6.4 Wood: Geographic Segmentation Analysis

7.7 High-Density Polyethylene

7.7.1 Introduction and Market Overview

7.7.2 Historic and Forecasted Market Size in Value USD and Volume Units (2017-2032F)

7.7.3 Key Market Trends, Growth Factors and Opportunities

7.7.4 High-Density Polyethylene : Geographic Segmentation Analysis

Chapter 8: Company Profiles and Competitive Analysis

8.1 Competitive Landscape

8.1.1 Competitive Benchmarking

8.1.2 Cooling Tower Market Share by Manufacturer (2023)

8.1.3 Industry BCG Matrix

8.1.4 Heat Map Analysis

8.1.5 Mergers and Acquisitions

8.2 EVAPCO (U.S.)

8.2.1 Company Overview

8.2.2 Key Executives

8.2.3 Company Snapshot

8.2.4 Role of the Company in the Market

8.2.5 Sustainability and Social Responsibility

8.2.6 Operating Business Segments

8.2.7 Product Portfolio

8.2.8 Business Performance

8.2.9 Key Strategic Moves and Recent Developments

8.2.10 SWOT Analysis

8.3 BALTIMORE AIRCOIL COMPANY INC. (U.S.)

8.4 SPX CORPORATION (U.S.)

8.5 ARTECH COOLING TOWERS PVT. LTD. (INDIA)

8.6 BABCOCK & WILCOX ENTERPRISES (U.S.)

8.7 BRENTWOOD INDUSTRIES (U.S.)

8.8 JOHNSON CONTROLS INC. (IRELAND)

8.9 PAHARPUR COOLING TOWER LTD. (INDIA)

8.10 ENEXIO MANAGEMENT GMBH (GERMANY)

8.11 HAMON & CIE INTERNATIONAL (BELGIUM)

8.12 BELL COOLING TOWERS (INDIA)

8.13 PAHARPUR COOLING TOWERS LTD. (INDIA)

8.14 BALTIMORE AIRCOIL COMPANY (U.S.)

8.15 CANNON WATER TECHNOLOGY (U.S.)

8.16 NALCO INDIA (INDIA)

8.17 PERFECT STAR HEATING AND AIR CONDITIONING INC (U.S.)

8.18 REYMSA COOLING TOWERS INC

8.19 (U.S.)

8.20 THERMAX LIMITED (INDIA)

8.21 DELTA COOLING TOWERS (U.S.)

8.22 INTERNATIONAL COOLING TOWER (CANADA)

8.23 STAR COOLING TOWERS (INDIA)

8.24 MESAN GROUP (CHINA)

8.25 OTHER ACTIVE PLAYERS

Chapter 9: Global Cooling Tower Market By Region

9.1 Overview

9.2. North America Cooling Tower Market

9.2.1 Key Market Trends, Growth Factors and Opportunities

9.2.2 Top Key Companies

9.2.3 Historic and Forecasted Market Size by Segments

9.2.4 Historic and Forecasted Market Size By Type

9.2.4.1 Open-Circuit Cooling Towers

9.2.4.2 Closed-Circuit Cooling Towers

9.2.4.3 Hybrid Cooling Towers

9.2.5 Historic and Forecasted Market Size By Application

9.2.5.1 Cross Flow

9.2.5.2 Counter Flow

9.2.6 Historic and Forecasted Market Size By Design

9.2.6.1 Mechanical Draft Cooling Tower

9.2.6.2 Natural Draft Cooling Tower

9.2.7 Historic and Forecasted Market Size By Construction Material

9.2.7.1 Fiber-Reinforced Plastic

9.2.7.2 Steel

9.2.7.3 Concrete

9.2.7.4 Wood

9.2.7.5 High-Density Polyethylene

9.2.8 Historic and Forecast Market Size by Country

9.2.8.1 US

9.2.8.2 Canada

9.2.8.3 Mexico

9.3. Eastern Europe Cooling Tower Market

9.3.1 Key Market Trends, Growth Factors and Opportunities

9.3.2 Top Key Companies

9.3.3 Historic and Forecasted Market Size by Segments

9.3.4 Historic and Forecasted Market Size By Type

9.3.4.1 Open-Circuit Cooling Towers

9.3.4.2 Closed-Circuit Cooling Towers

9.3.4.3 Hybrid Cooling Towers

9.3.5 Historic and Forecasted Market Size By Application

9.3.5.1 Cross Flow

9.3.5.2 Counter Flow

9.3.6 Historic and Forecasted Market Size By Design

9.3.6.1 Mechanical Draft Cooling Tower

9.3.6.2 Natural Draft Cooling Tower

9.3.7 Historic and Forecasted Market Size By Construction Material

9.3.7.1 Fiber-Reinforced Plastic

9.3.7.2 Steel

9.3.7.3 Concrete

9.3.7.4 Wood

9.3.7.5 High-Density Polyethylene

9.3.8 Historic and Forecast Market Size by Country

9.3.8.1 Russia

9.3.8.2 Bulgaria

9.3.8.3 The Czech Republic

9.3.8.4 Hungary

9.3.8.5 Poland

9.3.8.6 Romania

9.3.8.7 Rest of Eastern Europe

9.4. Western Europe Cooling Tower Market

9.4.1 Key Market Trends, Growth Factors and Opportunities

9.4.2 Top Key Companies

9.4.3 Historic and Forecasted Market Size by Segments

9.4.4 Historic and Forecasted Market Size By Type

9.4.4.1 Open-Circuit Cooling Towers

9.4.4.2 Closed-Circuit Cooling Towers

9.4.4.3 Hybrid Cooling Towers

9.4.5 Historic and Forecasted Market Size By Application

9.4.5.1 Cross Flow

9.4.5.2 Counter Flow

9.4.6 Historic and Forecasted Market Size By Design

9.4.6.1 Mechanical Draft Cooling Tower

9.4.6.2 Natural Draft Cooling Tower

9.4.7 Historic and Forecasted Market Size By Construction Material

9.4.7.1 Fiber-Reinforced Plastic

9.4.7.2 Steel

9.4.7.3 Concrete

9.4.7.4 Wood

9.4.7.5 High-Density Polyethylene

9.4.8 Historic and Forecast Market Size by Country

9.4.8.1 Germany

9.4.8.2 UK

9.4.8.3 France

9.4.8.4 The Netherlands

9.4.8.5 Italy

9.4.8.6 Spain

9.4.8.7 Rest of Western Europe

9.5. Asia Pacific Cooling Tower Market

9.5.1 Key Market Trends, Growth Factors and Opportunities

9.5.2 Top Key Companies

9.5.3 Historic and Forecasted Market Size by Segments

9.5.4 Historic and Forecasted Market Size By Type

9.5.4.1 Open-Circuit Cooling Towers

9.5.4.2 Closed-Circuit Cooling Towers

9.5.4.3 Hybrid Cooling Towers

9.5.5 Historic and Forecasted Market Size By Application

9.5.5.1 Cross Flow

9.5.5.2 Counter Flow

9.5.6 Historic and Forecasted Market Size By Design

9.5.6.1 Mechanical Draft Cooling Tower

9.5.6.2 Natural Draft Cooling Tower

9.5.7 Historic and Forecasted Market Size By Construction Material

9.5.7.1 Fiber-Reinforced Plastic

9.5.7.2 Steel

9.5.7.3 Concrete

9.5.7.4 Wood

9.5.7.5 High-Density Polyethylene

9.5.8 Historic and Forecast Market Size by Country

9.5.8.1 China

9.5.8.2 India

9.5.8.3 Japan

9.5.8.4 South Korea

9.5.8.5 Malaysia

9.5.8.6 Thailand

9.5.8.7 Vietnam

9.5.8.8 The Philippines

9.5.8.9 Australia

9.5.8.10 New Zealand

9.5.8.11 Rest of APAC

9.6. Middle East & Africa Cooling Tower Market

9.6.1 Key Market Trends, Growth Factors and Opportunities

9.6.2 Top Key Companies

9.6.3 Historic and Forecasted Market Size by Segments

9.6.4 Historic and Forecasted Market Size By Type

9.6.4.1 Open-Circuit Cooling Towers

9.6.4.2 Closed-Circuit Cooling Towers

9.6.4.3 Hybrid Cooling Towers

9.6.5 Historic and Forecasted Market Size By Application

9.6.5.1 Cross Flow

9.6.5.2 Counter Flow

9.6.6 Historic and Forecasted Market Size By Design

9.6.6.1 Mechanical Draft Cooling Tower

9.6.6.2 Natural Draft Cooling Tower

9.6.7 Historic and Forecasted Market Size By Construction Material

9.6.7.1 Fiber-Reinforced Plastic

9.6.7.2 Steel

9.6.7.3 Concrete

9.6.7.4 Wood

9.6.7.5 High-Density Polyethylene

9.6.8 Historic and Forecast Market Size by Country

9.6.8.1 Turkiye

9.6.8.2 Bahrain

9.6.8.3 Kuwait

9.6.8.4 Saudi Arabia

9.6.8.5 Qatar

9.6.8.6 UAE

9.6.8.7 Israel

9.6.8.8 South Africa

9.7. South America Cooling Tower Market

9.7.1 Key Market Trends, Growth Factors and Opportunities

9.7.2 Top Key Companies

9.7.3 Historic and Forecasted Market Size by Segments

9.7.4 Historic and Forecasted Market Size By Type

9.7.4.1 Open-Circuit Cooling Towers

9.7.4.2 Closed-Circuit Cooling Towers

9.7.4.3 Hybrid Cooling Towers

9.7.5 Historic and Forecasted Market Size By Application

9.7.5.1 Cross Flow

9.7.5.2 Counter Flow

9.7.6 Historic and Forecasted Market Size By Design

9.7.6.1 Mechanical Draft Cooling Tower

9.7.6.2 Natural Draft Cooling Tower

9.7.7 Historic and Forecasted Market Size By Construction Material

9.7.7.1 Fiber-Reinforced Plastic

9.7.7.2 Steel

9.7.7.3 Concrete

9.7.7.4 Wood

9.7.7.5 High-Density Polyethylene

9.7.8 Historic and Forecast Market Size by Country

9.7.8.1 Brazil

9.7.8.2 Argentina

9.7.8.3 Rest of SA

Chapter 10 Analyst Viewpoint and Conclusion

10.1 Recommendations and Concluding Analysis

10.2 Potential Market Strategies

Chapter 11 Research Methodology

11.1 Research Process

11.2 Primary Research

11.3 Secondary Research

Q1: What would be the forecast period in the Cooling Tower Market research report?

A1: The forecast period in the Cooling Tower Market research report is 2024-2032.

Q2: Who are the key players in the Cooling Tower Market?

A2: EVAPCO (U.S.), Baltimore Aircoil Company Inc. (U.S.), SPX Corporation (U.S.), Artech Cooling Towers Pvt. Ltd. (India), Babcock & Wilcox Enterprises (U.S.), Brentwood Industries (U.S.), Johnson Controls Inc. (Ireland), Paharpur Cooling Tower Ltd. (India), ENEXIO MANAGEMENT GMBH (Germany), Hamon & CIE International (Belgium), BELL COOLING TOWERS (India), Paharpur Cooling Towers Ltd. (India), Baltimore Aircoil Company (U.S.), Cannon Water Technology (U.S.), NALCO India (India), Perfect Star Heating and Air Conditioning, Inc (U.S.), REYMSA COOLING TOWERS, INC, (U.S.), Thermax Limited (India), Delta Cooling Towers (U.S.), International Cooling Tower (Canada), Star Cooling Towers (India), Mesan Group (China) and Other Active Players.

Q3: What are the segments of the Cooling Tower Market?

A3: The Cooling Tower Market is segmented into By Type, By Application, By Design, By Construction Material, By End-user and region. By Type, the market is categorized into Open-Circuit Cooling Towers, Closed-Circuit Cooling Towers, Hybrid Cooling Towers. By Application, the market is categorized into Cross Flow, Counter Flow. By Design, the market is categorized into Mechanical Draft Cooling Tower, Natural Draft Cooling Tower. By Construction Material, the market is categorized into Fiber-Reinforced Plastic (FRP), Steel, Concrete, Wood, High-Density Polyethylene (HDPE), Others. By End-user, the market is categorized into Chemical, HVAC, Petrochemicals and Oil and Gas, Power Generation, Food and Beverages, Others. By region, it is analyzed across North America (U.S., Canada, Mexico), Eastern Europe (Russia, Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe), Western Europe (Germany, UK, France, The Netherlands, Italy, Russia, Spain, Rest of Western Europe), Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New-Zealand, Rest of APAC), Middle East & Africa (Turkiye, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa), South America (Brazil, Argentina, Rest of SA).

Q4: What is the Cooling Tower Market?

A4: A cooling tower is a device that removes excess heat and depends on water to transfer the waste heat into the atmosphere. It offers many advantages, such as cost-effectiveness, energy efficiency, water conservation, optimal cooling and resistance against corrosion, ease of installation, high structural strength, longer service life, and reduced noise pollution. As a result, it is widely used in ventilation, heating, and air conditioning (HVAC) systems, power production, petroleum refineries, cold storage units, and food processing industries. Aside from that, it is utilized to provide comfortable cooling in large commercial facilities such as hospitals, airports, schools, and hotels, among others.

Q5: How big is the Cooling Tower Market?

A5: Cooling Tower Market Size Was Valued at USD 3.85 Billion in 2023, and is Projected to Reach USD 5.72 Billion by 2032, Growing at a CAGR of 4.50% From 2024-2032.

How to Buy a Report from eminsights.jp

On the product page, choose the license you want: Single-User License, Multi-User License or Enterprise License.

If you required report in your native language, then you can click on Translated Report button and fill out the form with report name and language you want, then our team will contact you as soon as possible.

Click the Buy Now button.

You will be redirected to the checkout page. Enter your company details and payment information.

Click Place Order to complete the purchase.

Confirmation: You’ll receive an order confirmation and our team will contact you shortly with your ordered report.

If you have any questions, fill out the contact form below or email us at bizdev@eminsights.net.

Thank you for choosing eminsights.jp!