Stay Ahead in Fast-Growing Economies.

Browse Reports NowBakery Processing Equipment Market Size & Upcoming Industry

Bakery processing equipment is designed to automate different stages of the baking process, consisting of specialized machinery and tools for producing baked goods. This machinery includes mixers that blend necessary components such as flour, water, and yeast, as well as dividers that separate dough into uniform portions.

IMR Group

Description

Bakery Processing Equipment Market Synopsis

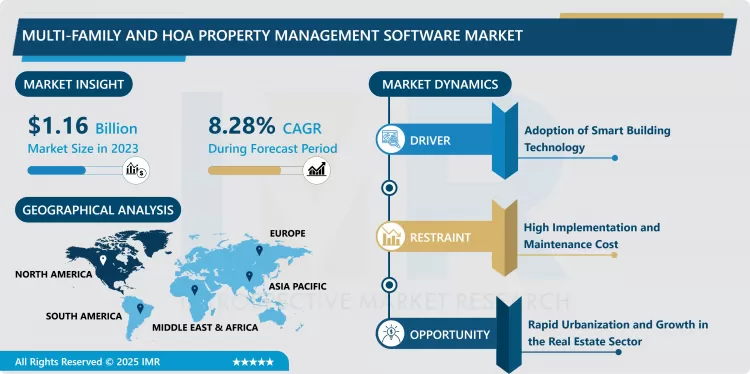

Bakery Processing Equipment Market Size Was Valued at USD 18.62 Billion in 2023 and is Projected to Reach USD 31.32 Billion by 2032, Growing at a CAGR of 5.95% From 2024-2032.

Bakery processing equipment is designed to automate different stages of the baking process, consisting of specialized machinery and tools for producing baked goods. This machinery includes mixers that blend necessary components such as flour, water, and yeast, as well as dividers that separate dough into uniform portions. Changes in consumer behavior and shifting preferences have caused food producers to create new products to meet evolving needs for taste, flavor, and nutrients, resulting in more complex production processes. This has increased the demand for modern bakery processing equipment that can manage different ingredients and carry out numerous functions. Bakery producers are focusing on enhancing production efficiency in response to increasing costs of energy, labor, and raw materials by integrating high-tech bakery processing equipment into their operations to boost profits.

Automation in machinery increases the speed of production, and adaptability, and cuts labor expenses by reducing the need for human involvement. Anticipated growth in the demand for automated bakery processing equipment is driven by its ability to enhance efficiency, decrease waste, and satisfy consumer expectations for uniform and premium bakery products. The bakery processing equipment industry is expected to experience growth due to increasing consumer demand for high-quality equipment, continual product improvements, and more stringent government regulations. Additionally, the increasing prevalence of advertisements featuring attractive marketing materials and a wide range of flavors in processed food is anticipated to enhance their popularity, driving the need for bakery processing machinery.

Bakery Processing Equipment Market Trend Analysis

Bakery Inclusions Provide Health Benefits and Delicious Flavours

Consumers are seeking healthier bakery products, containing high fiber, protein, vitamins, minerals, and lower sugar content. Traditional recipes incorporate seeds, nuts, dried fruits, whole grains, and superfoods. This pattern is leading to a greater need for bakery equipment capable of handling these ingredients. Consumers are looking for bakery products that offer a variety of flavors such as dark chocolate chips, fruit pieces, caramel swirls, and exotic spices.

Specialized equipment is required to evenly mix these inclusions and maintain product quality to meet demand. Bakeries require adaptable and personalized machinery while they test out new ingredients. Machines capable of processing different kinds of inclusions enable bakeries to adjust to consumer tastes and introduce new products without the need for additional equipment.

Equipment makers are designing sophisticated mixers to evenly disperse health-conscious and tasty additives such as nuts or dried fruits. High-shear mixers, planetary mixers, and specialized blending machines are needed for improved mixing abilities. Consumers’ growing preference for clean-label products, made with simple, natural ingredients free from artificial additives, has led to demand for gentle processing equipment to preserve the nutritional value and flavor of bakery inclusions like organic nuts and naturally sweetened dried fruits.

Increasing Desire for Vegan and Plant-Based Bakery Items Is on The Rise

With an increasing number of customers requesting vegan and plant-based bakery items, the demand for creative substitutes for conventional baking ingredients such as eggs, dairy, and honey is rising. This results in the creation of innovative ingredient formulations and influences the necessary processing equipment in bakeries. Specific tools are needed to manage the distinct characteristics of plant-derived ingredients to ensure the best possible texture and flavor.

Bakeries are increasing their production capacity to meet the growing demand for vegan products. They are making investments in cutting-edge processing equipment and automated systems to boost efficiency and uniformity while cutting down on labor expenses. New technologies and equipment are being developed to cater to the unique needs of vegan and plant-based baking. This includes equipment designed to handle alternative flours, proteins, and fats, which can behave differently than traditional baking ingredients.

Advanced equipment for quality control and monitoring ensures that vegan and plant-based products meet consumer expectations in terms of texture, flavor, and appearance. This includes precise temperature and humidity controls, as well as real-time monitoring systems. The rise in vegan and plant-based baking is expanding the market for bakery processing equipment into new segments. Equipment manufacturers are exploring opportunities to produce machines specifically designed for plant-based ingredients, catering to niche markets that are growing rapidly.

Bakery Processing Equipment Market Segment Analysis:

The Bakery Processing Equipment Market is Segmented on the basis of Equipment Type, Mode of Operation, Function, Application, End-User, And Region.

By EquipmentEquipment Type, Ovens Segment Is Expected to Dominate the Market During the Forecast Period

Ovens are essential in the baking process as they transform dough into final products such as bread, cakes, and cookies. They are necessary tools for running a bakery. Rising international desire for baked products has resulted in a necessity for trustworthy ovens, particularly in increasingly urban areas with high levels of bakery consumption, leading to an increased need for innovative baking technology.

Automated ovens play a crucial role in bakery automation by improving efficiency, cutting labor expenses, and optimizing operations. Connecting with additional systems such as verifiers and refrigerators strengthens their importance. Ovens play a crucial role in bakeries of every size, whether they are small artisanal shops or large industrial facilities because they can accommodate a wide range of products.

Bakeries need top-notch ovens that adhere to strict health and safety rules to guarantee the safe manufacturing of products. Adherence to regulations creates a need for up-to-date, effective ovens to uphold productivity and product standards. Bakery ovens are upgraded or replaced to keep up with technology, save energy, and meet production demands. Tailored features address the unique needs of bakeries, strengthening the market position of oven producers.

By Application, Breads Segment Held the Largest Share In 2023

The bakery industry sees strong demand for items such as bread, pastries, cakes, and cookies worldwide, making it the primary sector for bakery processing equipment because consumers favor easy-to-eat foods. Bakeries provide a range of items, such as bread and fancy pastries, that need various cooking tools like mixers, ovens, proofers, and slicers. This results in a significant need for a variety of machinery, with bakeries being the primary consumers of processing equipment.

The bakery sector is changing with the introduction of new product options such as gluten-free, organic, and artisanal items, necessitating sophisticated processing machinery to facilitate advancements in manufacturing techniques. Bakeries are increasingly using automation to improve efficiency to meet demand and offer competitive prices. Automated bakery machinery increases production levels by maintaining uniformity, excellence, and productivity, widely used in large-scale bakeries.

Increasing knowledge about health drives the popularity of healthier bakery items such as whole-grain bread and cakes with reduced sugar content. This necessitates specialized processing methods and machinery, leading to higher investments in bakery equipment. The demand for standardized bakery processing equipment is increasing due to the globalization of bakery brands and urbanization. Consistent equipment is necessary for quality and efficiency when international chains expand into new markets. As dietary habits evolve, more people in cities are opting for bakery products for their convenience, resulting in a greater need for bakery processing equipment.

Bakery Processing Equipment Market Regional Insights:

Asia Pacific is Expected to Dominate the Market Over the Forecast Period

The Asia-Pacific region is witnessing rapid urbanization in China and India, resulting in population expansion and a higher need for processed foods like baked goods. Large bakery operations on a large scale are necessary to keep up with the increasing demand. The growing economy in China, India, and Southeast Asia is boosting disposable incomes, resulting in increased consumer spending on convenience foods and bakery products. The rise in this trend is increasing the need for modern bakery processing equipment to improve production efficiency.

The food and beverage sector in Asia-Pacific is quickly growing, as both local and international bakery companies are increasing, thus driving up the need for modern bakery processing machinery. Countries in the Asia-Pacific region are making investments in technology for food processing, which is resulting in a notable increase in automated bakery processing equipment. Businesses in the area are utilizing modern technologies to enhance manufacturing procedures and fulfill customer needs.

Growing interest in Western-style baked products in Asia-Pacific nations as a result of being influenced by global food trends. Bakeries are upgrading their processing equipment to keep up with the increasing demand for bread, pastries, and cakes. Governments in the Asia-Pacific region offer subsidies, tax incentives, and infrastructure development to support the food processing sector, which helps drive growth in the bakery processing industry and encourages the adoption of advanced equipment.

Bakery Processing Equipment Market Active Players

Buhler Group (Switzerland)

Baker Perkins (UK)

The Middleby Corporation (USA)

JBT Corporation (USA)

Moline Machinery (USA)

Alba Manufacturing (USA)

Rheon Automatic Machinery (Japan)

AMF Bakery Systems (USA)

GEA Group (Germany)

Rondo (Germany)

Fritsch (Germany)

Haas-Mondomix (Netherlands)

Sottoriva (Italy)

WP Bakery Group (Germany)

Sama Engineering (India)

Groupe GSP (France)

GAS Technologies (Italy)

SUGA International (Hong Kong)

Biro Manufacturing (USA)

Consolidated Biscuit (USA)

Omas Industries (Italy)

Bettendorf Stirling (USA)

Coperion (Germany)

Schulz Systemtechnik (Germany), and Other Active Players.

Key Industry Developments in the Bakery Processing Equipment Market:

In July 2024, Bühler hosts 80 game-changing start-ups as part of the MassChallenge program. Despite a reduction in start-up funding in recent years due to challenging economic markets, start-ups still have the opportunity to launch and grow thanks to accelerator programs that provide access to vital networks and resources.

In March 2024, Climate tech venture capital fund, Icos Capital, held the “Collaborative Innovation Summit” at Bühler’s CUBIC Innovation Campus on February 29, 2024. The event brought together inves

Chapter 1: Introduction

1.1 Scope and Coverage

Chapter 2:Executive Summary

Chapter 3: Market Landscape

3.1 Market Dynamics

3.1.1 Drivers

3.1.2 Restraints

3.1.3 Opportunities

3.1.4 Challenges

3.2 Market Trend Analysis

3.3 PESTLE Analysis

3.4 Porter’s Five Forces Analysis

3.5 Industry Value Chain Analysis

3.6 Ecosystem

3.7 Regulatory Landscape

3.8 Price Trend Analysis

3.9 Patent Analysis

3.10 Technology Evolution

3.11 Investment Pockets

3.12 Import-Export Analysis

Chapter 4: Bakery Processing Equipment Market by Equipment Type (2018-2032)

4.1 Bakery Processing Equipment Market Snapshot and Growth Engine

4.2 Market Overview

4.3 Ovens

4.3.1 Introduction and Market Overview

4.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

4.3.3 Key Market Trends, Growth Factors, and Opportunities

4.3.4 Geographic Segmentation Analysis

4.4 Mixers

4.5 Slicers and Dividers

4.6 Proofers

4.7 Retarders

4.8 Other {Freezers and Coolers

4.9 Chillers

4.10 Dough Feeding Systems

4.11 Pan Greasers and Depositors

4.12 Handling Systems

4.13 Piston Filling Injectors}

Chapter 5: Bakery Processing Equipment Market by Mode Of Operation (2018-2032)

5.1 Bakery Processing Equipment Market Snapshot and Growth Engine

5.2 Market Overview

5.3 Automatic

5.3.1 Introduction and Market Overview

5.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

5.3.3 Key Market Trends, Growth Factors, and Opportunities

5.3.4 Geographic Segmentation Analysis

5.4 Semi-Automatic

Chapter 6: Bakery Processing Equipment Market by Function (2018-2032)

6.1 Bakery Processing Equipment Market Snapshot and Growth Engine

6.2 Market Overview

6.3 Baking

6.3.1 Introduction and Market Overview

6.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

6.3.3 Key Market Trends, Growth Factors, and Opportunities

6.3.4 Geographic Segmentation Analysis

6.4 Kneading

6.5 Mixing

6.6 Cooling

6.7 Molding

6.8 Other {Filling

6.9 Enrobing}

Chapter 7: Bakery Processing Equipment Market by Application (2018-2032)

7.1 Bakery Processing Equipment Market Snapshot and Growth Engine

7.2 Market Overview

7.3 Cookies & Biscuits

7.3.1 Introduction and Market Overview

7.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

7.3.3 Key Market Trends, Growth Factors, and Opportunities

7.3.4 Geographic Segmentation Analysis

7.4 Breads

7.5 Cakes & Pastries

7.6 Donuts & Croissants

7.7 Pizza

7.8 Others {Crusts

7.9 Muffins

7.10 Bagels

7.11 Crackers

7.12 Pies

7.13 Waffles}

Chapter 8: Bakery Processing Equipment Market by End-User (2018-2032)

8.1 Bakery Processing Equipment Market Snapshot and Growth Engine

8.2 Market Overview

8.3 Bakery Processing Industry

8.3.1 Introduction and Market Overview

8.3.2 Historic and Forecasted Market Size in Value USD and Volume Units

8.3.3 Key Market Trends, Growth Factors, and Opportunities

8.3.4 Geographic Segmentation Analysis

8.4 Food Service Industry

Chapter 9: Company Profiles and Competitive Analysis

9.1 Competitive Landscape

9.1.1 Competitive Benchmarking

9.1.2 Bakery Processing Equipment Market Share by Manufacturer (2024)

9.1.3 Industry BCG Matrix

9.1.4 Heat Map Analysis

9.1.5 Mergers and Acquisitions

9.2 BUHLER GROUP (SWITZERLAND)

9.2.1 Company Overview

9.2.2 Key Executives

9.2.3 Company Snapshot

9.2.4 Role of the Company in the Market

9.2.5 Sustainability and Social Responsibility

9.2.6 Operating Business Segments

9.2.7 Product Portfolio

9.2.8 Business Performance

9.2.9 Key Strategic Moves and Recent Developments

9.2.10 SWOT Analysis

9.3 BAKER PERKINS (UK)

9.4 THE MIDDLEBY CORPORATION (USA)

9.5 JBT CORPORATION (USA)

9.6 MOLINE MACHINERY (USA)

9.7 ALBA MANUFACTURING (USA)

9.8 RHEON AUTOMATIC MACHINERY (JAPAN)

9.9 AMF BAKERY SYSTEMS (USA)

9.10 GEA GROUP (GERMANY)

9.11 RONDO (GERMANY)

9.12 FRITSCH (GERMANY)

9.13 HAAS-MONDOMIX (NETHERLANDS)

9.14 SOTTORIVA (ITALY)

9.15 WP BAKERY GROUP (GERMANY)

9.16 SAMA ENGINEERING (INDIA)

9.17 GROUPE GSP (FRANCE)

9.18 GAS TECHNOLOGIES (ITALY)

9.19 SUGA INTERNATIONAL (HONG KONG)

9.20 BIRO MANUFACTURING (USA)

9.21 CONSOLIDATED BISCUIT (USA)

9.22 OMAS INDUSTRIES (ITALY)

9.23 BETTENDORF STIRLING (USA)

9.24 COPERION (GERMANY)

9.25 SCHULZ SYSTEMTECHNIK (GERMANY)

9.26 AND

Chapter 10: Global Bakery Processing Equipment Market By Region

10.1 Overview

10.2. North America Bakery Processing Equipment Market

10.2.1 Key Market Trends, Growth Factors and Opportunities

10.2.2 Top Key Companies

10.2.3 Historic and Forecasted Market Size by Segments

10.2.4 Historic and Forecasted Market Size by Equipment Type

10.2.4.1 Ovens

10.2.4.2 Mixers

10.2.4.3 Slicers and Dividers

10.2.4.4 Proofers

10.2.4.5 Retarders

10.2.4.6 Other {Freezers and Coolers

10.2.4.7 Chillers

10.2.4.8 Dough Feeding Systems

10.2.4.9 Pan Greasers and Depositors

10.2.4.10 Handling Systems

10.2.4.11 Piston Filling Injectors}

10.2.5 Historic and Forecasted Market Size by Mode Of Operation

10.2.5.1 Automatic

10.2.5.2 Semi-Automatic

10.2.6 Historic and Forecasted Market Size by Function

10.2.6.1 Baking

10.2.6.2 Kneading

10.2.6.3 Mixing

10.2.6.4 Cooling

10.2.6.5 Molding

10.2.6.6 Other {Filling

10.2.6.7 Enrobing}

10.2.7 Historic and Forecasted Market Size by Application

10.2.7.1 Cookies & Biscuits

10.2.7.2 Breads

10.2.7.3 Cakes & Pastries

10.2.7.4 Donuts & Croissants

10.2.7.5 Pizza

10.2.7.6 Others {Crusts

10.2.7.7 Muffins

10.2.7.8 Bagels

10.2.7.9 Crackers

10.2.7.10 Pies

10.2.7.11 Waffles}

10.2.8 Historic and Forecasted Market Size by End-User

10.2.8.1 Bakery Processing Industry

10.2.8.2 Food Service Industry

10.2.9 Historic and Forecast Market Size by Country

10.2.9.1 US

10.2.9.2 Canada

10.2.9.3 Mexico

10.3. Eastern Europe Bakery Processing Equipment Market

10.3.1 Key Market Trends, Growth Factors and Opportunities

10.3.2 Top Key Companies

10.3.3 Historic and Forecasted Market Size by Segments

10.3.4 Historic and Forecasted Market Size by Equipment Type

10.3.4.1 Ovens

10.3.4.2 Mixers

10.3.4.3 Slicers and Dividers

10.3.4.4 Proofers

10.3.4.5 Retarders

10.3.4.6 Other {Freezers and Coolers

10.3.4.7 Chillers

10.3.4.8 Dough Feeding Systems

10.3.4.9 Pan Greasers and Depositors

10.3.4.10 Handling Systems

10.3.4.11 Piston Filling Injectors}

10.3.5 Historic and Forecasted Market Size by Mode Of Operation

10.3.5.1 Automatic

10.3.5.2 Semi-Automatic

10.3.6 Historic and Forecasted Market Size by Function

10.3.6.1 Baking

10.3.6.2 Kneading

10.3.6.3 Mixing

10.3.6.4 Cooling

10.3.6.5 Molding

10.3.6.6 Other {Filling

10.3.6.7 Enrobing}

10.3.7 Historic and Forecasted Market Size by Application

10.3.7.1 Cookies & Biscuits

10.3.7.2 Breads

10.3.7.3 Cakes & Pastries

10.3.7.4 Donuts & Croissants

10.3.7.5 Pizza

10.3.7.6 Others {Crusts

10.3.7.7 Muffins

10.3.7.8 Bagels

10.3.7.9 Crackers

10.3.7.10 Pies

10.3.7.11 Waffles}

10.3.8 Historic and Forecasted Market Size by End-User

10.3.8.1 Bakery Processing Industry

10.3.8.2 Food Service Industry

10.3.9 Historic and Forecast Market Size by Country

10.3.9.1 Russia

10.3.9.2 Bulgaria

10.3.9.3 The Czech Republic

10.3.9.4 Hungary

10.3.9.5 Poland

10.3.9.6 Romania

10.3.9.7 Rest of Eastern Europe

10.4. Western Europe Bakery Processing Equipment Market

10.4.1 Key Market Trends, Growth Factors and Opportunities

10.4.2 Top Key Companies

10.4.3 Historic and Forecasted Market Size by Segments

10.4.4 Historic and Forecasted Market Size by Equipment Type

10.4.4.1 Ovens

10.4.4.2 Mixers

10.4.4.3 Slicers and Dividers

10.4.4.4 Proofers

10.4.4.5 Retarders

10.4.4.6 Other {Freezers and Coolers

10.4.4.7 Chillers

10.4.4.8 Dough Feeding Systems

10.4.4.9 Pan Greasers and Depositors

10.4.4.10 Handling Systems

10.4.4.11 Piston Filling Injectors}

10.4.5 Historic and Forecasted Market Size by Mode Of Operation

10.4.5.1 Automatic

10.4.5.2 Semi-Automatic

10.4.6 Historic and Forecasted Market Size by Function

10.4.6.1 Baking

10.4.6.2 Kneading

10.4.6.3 Mixing

10.4.6.4 Cooling

10.4.6.5 Molding

10.4.6.6 Other {Filling

10.4.6.7 Enrobing}

10.4.7 Historic and Forecasted Market Size by Application

10.4.7.1 Cookies & Biscuits

10.4.7.2 Breads

10.4.7.3 Cakes & Pastries

10.4.7.4 Donuts & Croissants

10.4.7.5 Pizza

10.4.7.6 Others {Crusts

10.4.7.7 Muffins

10.4.7.8 Bagels

10.4.7.9 Crackers

10.4.7.10 Pies

10.4.7.11 Waffles}

10.4.8 Historic and Forecasted Market Size by End-User

10.4.8.1 Bakery Processing Industry

10.4.8.2 Food Service Industry

10.4.9 Historic and Forecast Market Size by Country

10.4.9.1 Germany

10.4.9.2 UK

10.4.9.3 France

10.4.9.4 The Netherlands

10.4.9.5 Italy

10.4.9.6 Spain

10.4.9.7 Rest of Western Europe

10.5. Asia Pacific Bakery Processing Equipment Market

10.5.1 Key Market Trends, Growth Factors and Opportunities

10.5.2 Top Key Companies

10.5.3 Historic and Forecasted Market Size by Segments

10.5.4 Historic and Forecasted Market Size by Equipment Type

10.5.4.1 Ovens

10.5.4.2 Mixers

10.5.4.3 Slicers and Dividers

10.5.4.4 Proofers

10.5.4.5 Retarders

10.5.4.6 Other {Freezers and Coolers

10.5.4.7 Chillers

10.5.4.8 Dough Feeding Systems

10.5.4.9 Pan Greasers and Depositors

10.5.4.10 Handling Systems

10.5.4.11 Piston Filling Injectors}

10.5.5 Historic and Forecasted Market Size by Mode Of Operation

10.5.5.1 Automatic

10.5.5.2 Semi-Automatic

10.5.6 Historic and Forecasted Market Size by Function

10.5.6.1 Baking

10.5.6.2 Kneading

10.5.6.3 Mixing

10.5.6.4 Cooling

10.5.6.5 Molding

10.5.6.6 Other {Filling

10.5.6.7 Enrobing}

10.5.7 Historic and Forecasted Market Size by Application

10.5.7.1 Cookies & Biscuits

10.5.7.2 Breads

10.5.7.3 Cakes & Pastries

10.5.7.4 Donuts & Croissants

10.5.7.5 Pizza

10.5.7.6 Others {Crusts

10.5.7.7 Muffins

10.5.7.8 Bagels

10.5.7.9 Crackers

10.5.7.10 Pies

10.5.7.11 Waffles}

10.5.8 Historic and Forecasted Market Size by End-User

10.5.8.1 Bakery Processing Industry

10.5.8.2 Food Service Industry

10.5.9 Historic and Forecast Market Size by Country

10.5.9.1 China

10.5.9.2 India

10.5.9.3 Japan

10.5.9.4 South Korea

10.5.9.5 Malaysia

10.5.9.6 Thailand

10.5.9.7 Vietnam

10.5.9.8 The Philippines

10.5.9.9 Australia

10.5.9.10 New Zealand

10.5.9.11 Rest of APAC

10.6. Middle East & Africa Bakery Processing Equipment Market

10.6.1 Key Market Trends, Growth Factors and Opportunities

10.6.2 Top Key Companies

10.6.3 Historic and Forecasted Market Size by Segments

10.6.4 Historic and Forecasted Market Size by Equipment Type

10.6.4.1 Ovens

10.6.4.2 Mixers

10.6.4.3 Slicers and Dividers

10.6.4.4 Proofers

10.6.4.5 Retarders

10.6.4.6 Other {Freezers and Coolers

10.6.4.7 Chillers

10.6.4.8 Dough Feeding Systems

10.6.4.9 Pan Greasers and Depositors

10.6.4.10 Handling Systems

10.6.4.11 Piston Filling Injectors}

10.6.5 Historic and Forecasted Market Size by Mode Of Operation

10.6.5.1 Automatic

10.6.5.2 Semi-Automatic

10.6.6 Historic and Forecasted Market Size by Function

10.6.6.1 Baking

10.6.6.2 Kneading

10.6.6.3 Mixing

10.6.6.4 Cooling

10.6.6.5 Molding

10.6.6.6 Other {Filling

10.6.6.7 Enrobing}

10.6.7 Historic and Forecasted Market Size by Application

10.6.7.1 Cookies & Biscuits

10.6.7.2 Breads

10.6.7.3 Cakes & Pastries

10.6.7.4 Donuts & Croissants

10.6.7.5 Pizza

10.6.7.6 Others {Crusts

10.6.7.7 Muffins

10.6.7.8 Bagels

10.6.7.9 Crackers

10.6.7.10 Pies

10.6.7.11 Waffles}

10.6.8 Historic and Forecasted Market Size by End-User

10.6.8.1 Bakery Processing Industry

10.6.8.2 Food Service Industry

10.6.9 Historic and Forecast Market Size by Country

10.6.9.1 Turkiye

10.6.9.2 Bahrain

10.6.9.3 Kuwait

10.6.9.4 Saudi Arabia

10.6.9.5 Qatar

10.6.9.6 UAE

10.6.9.7 Israel

10.6.9.8 South Africa

10.7. South America Bakery Processing Equipment Market

10.7.1 Key Market Trends, Growth Factors and Opportunities

10.7.2 Top Key Companies

10.7.3 Historic and Forecasted Market Size by Segments

10.7.4 Historic and Forecasted Market Size by Equipment Type

10.7.4.1 Ovens

10.7.4.2 Mixers

10.7.4.3 Slicers and Dividers

10.7.4.4 Proofers

10.7.4.5 Retarders

10.7.4.6 Other {Freezers and Coolers

10.7.4.7 Chillers

10.7.4.8 Dough Feeding Systems

10.7.4.9 Pan Greasers and Depositors

10.7.4.10 Handling Systems

10.7.4.11 Piston Filling Injectors}

10.7.5 Historic and Forecasted Market Size by Mode Of Operation

10.7.5.1 Automatic

10.7.5.2 Semi-Automatic

10.7.6 Historic and Forecasted Market Size by Function

10.7.6.1 Baking

10.7.6.2 Kneading

10.7.6.3 Mixing

10.7.6.4 Cooling

10.7.6.5 Molding

10.7.6.6 Other {Filling

10.7.6.7 Enrobing}

10.7.7 Historic and Forecasted Market Size by Application

10.7.7.1 Cookies & Biscuits

10.7.7.2 Breads

10.7.7.3 Cakes & Pastries

10.7.7.4 Donuts & Croissants

10.7.7.5 Pizza

10.7.7.6 Others {Crusts

10.7.7.7 Muffins

10.7.7.8 Bagels

10.7.7.9 Crackers

10.7.7.10 Pies

10.7.7.11 Waffles}

10.7.8 Historic and Forecasted Market Size by End-User

10.7.8.1 Bakery Processing Industry

10.7.8.2 Food Service Industry

10.7.9 Historic and Forecast Market Size by Country

10.7.9.1 Brazil

10.7.9.2 Argentina

10.7.9.3 Rest of SA

Chapter 11 Analyst Viewpoint and Conclusion

11.1 Recommendations and Concluding Analysis

11.2 Potential Market Strategies

Chapter 12 Research Methodology

12.1 Research Process

12.2 Primary Research

12.3 Secondary Research

Q1: What would be the forecast period in the Bakery Processing Equipment Market research report?

A1: The forecast period in the Bakery Processing Equipment Market research report is 2024-2032.

Q2: Who are the key players in the Bakery Processing Equipment Market?

A2: Buhler Group (Switzerland), Baker Perkins (UK), The Middleby Corporation (USA), JBT Corporation (USA), Moline Machinery (USA), Alba Manufacturing (USA), Rheon Automatic Machinery (Japan), AMF Bakery Systems (USA), GEA Group (Germany), Rondo (Germany), Fritsch (Germany), Haas-Mondomix (Netherlands), Sottoriva (Italy), WP Bakery Group (Germany), Sama Engineering (India), Groupe GSP (France), GAS Technologies (Italy), SUGA International (Hong Kong), Biro Manufacturing (USA), Consolidated Biscuit (USA), Omas Industries (Italy), Bettendorf Stirling (USA), Coperion (Germany), Schulz Systemtechnik (Germany)and Other Active Players.

Q3: What are the segments of the Bakery Processing Equipment Market?

A3: The Bakery Processing Equipment Market is segmented into Equipment Type, Mode of Operation, Function, Application, End-User, and region. By Equipment Type, the market is categorized into Ovens, Mixers, Slicers and Dividers, Proofers, Retarders, And Other {Freezers and Coolers, Chillers, Dough Feeding Systems, Pan Greasers and Depositors, Handling Systems, Piston Filling Injectors}. By Mode Of Operation, the market is categorized into Automatic and semi-automatic Semi-Automatic, By Function, the market is categorized into Baking, Kneading, Mixing, Cooling, Molding, And Other{Filling, Enrobing}. By Application, the market is categorized into Cookies & Biscuits, Bread, Cakes & Pastries, Donuts & Croissants, Pizza, And Others {Crusts, Muffins, Bagels, Crackers, Pies, Waffles}. By End-User, The Market Is Categorized Into the Bakery Processing Industry and Food Service Industry. By region, it is analyzed across North America (U.S.; Canada; Mexico), Eastern Europe (Bulgaria; The Czech Republic; Hungary; Poland; Romania; Rest of Eastern Europe), Western Europe (Germany; UK; France; Netherlands; Italy; Russia; Spain; Rest of Western Europe), Asia-Pacific (China; India; Japan; Southeast Asia, etc.), South America (Brazil; Argentina, etc.), Middle East & Africa (Saudi Arabia; South Africa, etc.).

Q4: What is the Bakery Processing Equipment Market?

A4: Bakery processing equipment is designed to automate different stages of the baking process, consisting of specialized machinery and tools for producing baked goods. This machinery includes mixers that blend necessary components such as flour, water, and yeast, as well as dividers that separate dough into uniform portions.

Q5: How big is the Bakery Processing Equipment Market?

A5: Bakery Processing Equipment Market Size Was Valued at USD 18.62 Billion in 2023 and is Projected to Reach USD 31.32 Billion by 2032, Growing at a CAGR of 5.95% From 2024-2032.

How to Buy a Report from eminsights.jp

On the product page, choose the license you want: Single-User License, Multi-User License or Enterprise License.

If you required report in your native language, then you can click on Translated Report button and fill out the form with report name and language you want, then our team will contact you as soon as possible.

Click the Buy Now button.

You will be redirected to the checkout page. Enter your company details and payment information.

Click Place Order to complete the purchase.

Confirmation: You’ll receive an order confirmation and our team will contact you shortly with your ordered report.

If you have any questions, fill out the contact form below or email us at bizdev@eminsights.net.

Thank you for choosing eminsights.jp!